We have incorporated modern components with the highest level of safety SIL 4 into traditional technologies.

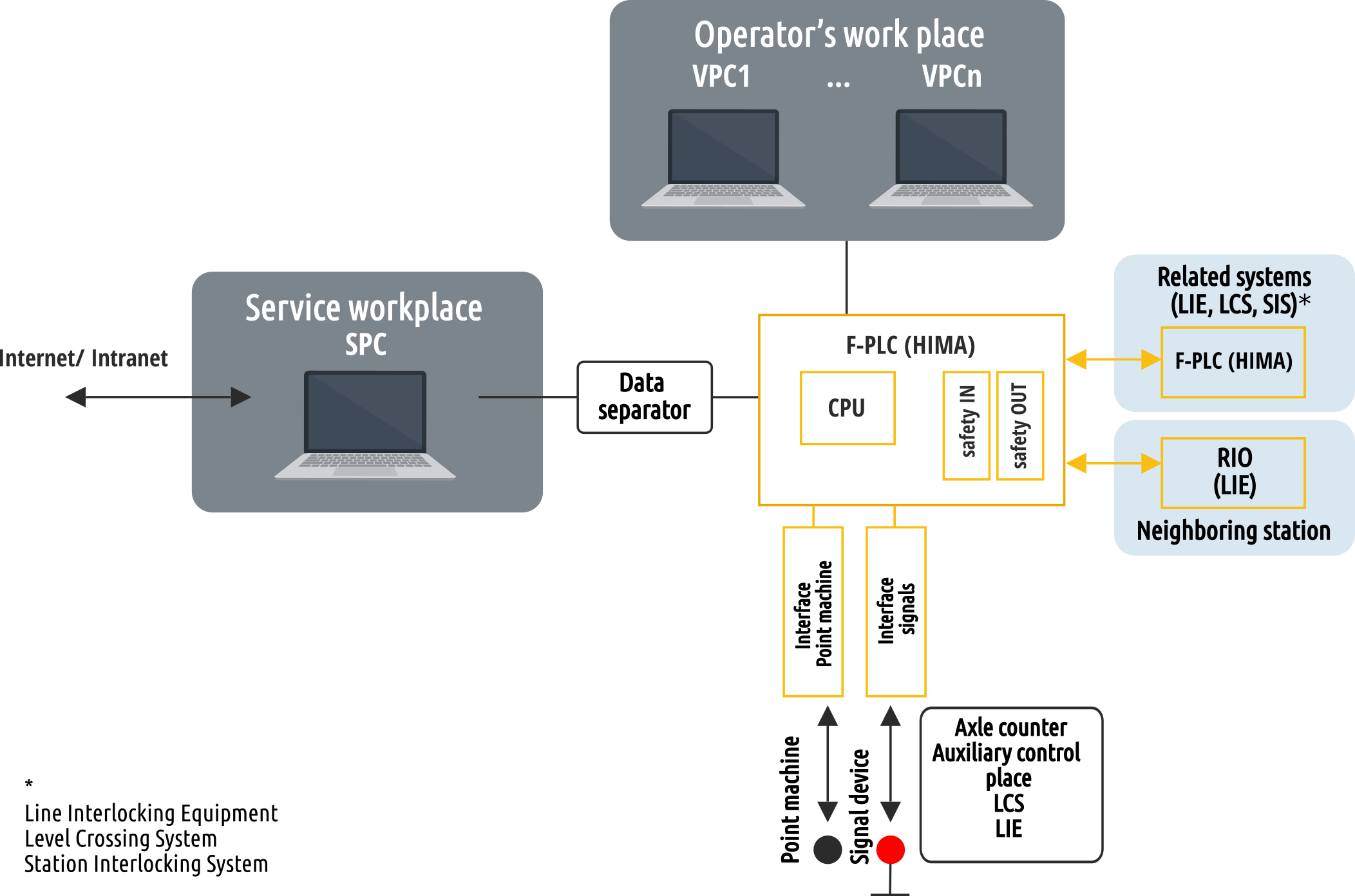

ProES

Fully Electronic Station

Interlocking System

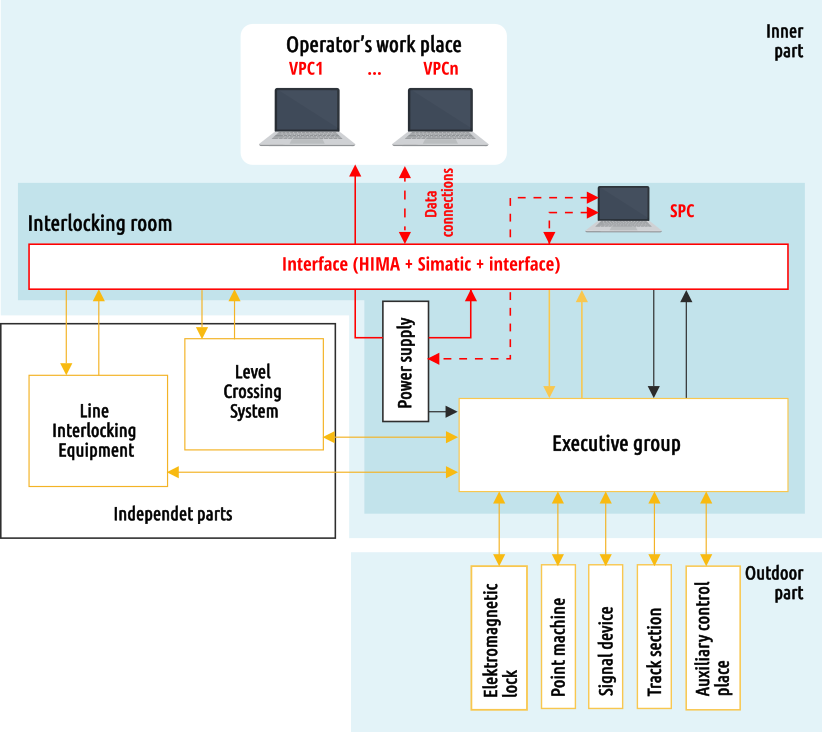

- Electronic interface for connection of outdoor components

- The basis is safety PLC HIMA

- Safety on SIL4 level

- Support of the multi-operator workplace

- Integrated line signalling system

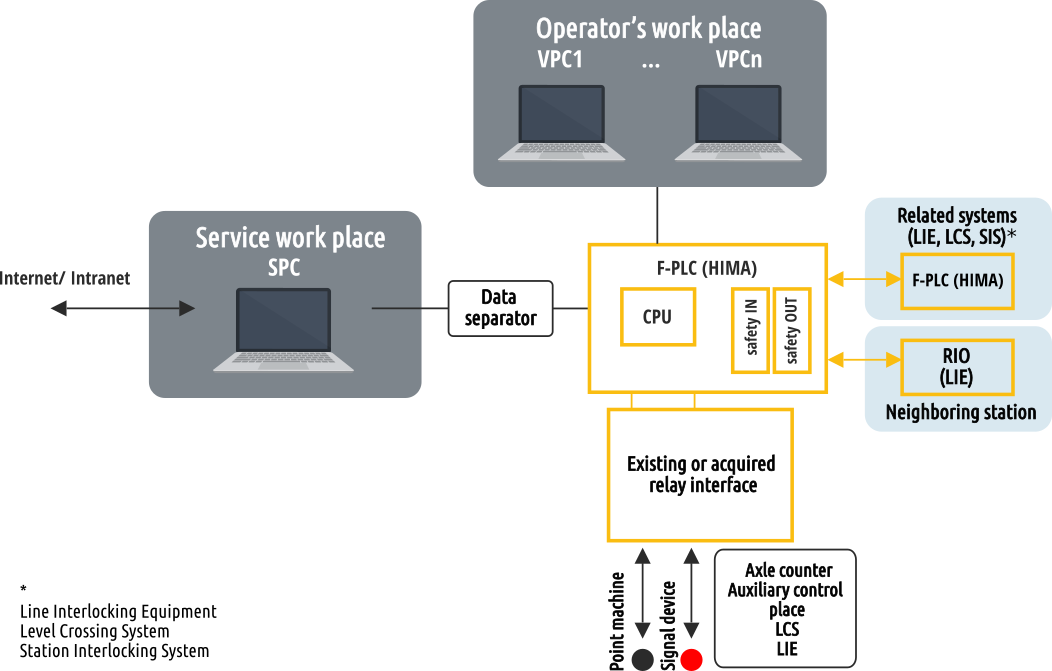

ProEH

Hybrid Station

Interlocking System

- Connection to outdoor components using the existing relay interlocking system

- It allows a combination of existing interfaces with an electronic interfaces

- Ideal for gradual change from relay interlocking system to the electronic station interlocking systems

- The basis is safety PLC HIMA

- Safety on SIL4 level

- Support of the multi-operator workplace

- Integrated line signalling system

ProEN

Extension for Relay Station

Interlocking Systems

- Connection to various types of relays station interlocking systems

- The basis is safety PLC HIMA

- Safety on SIL4 level

- Support of the multi-operator workplace

- Integrated line signalling system